Curtain Wall Attachment

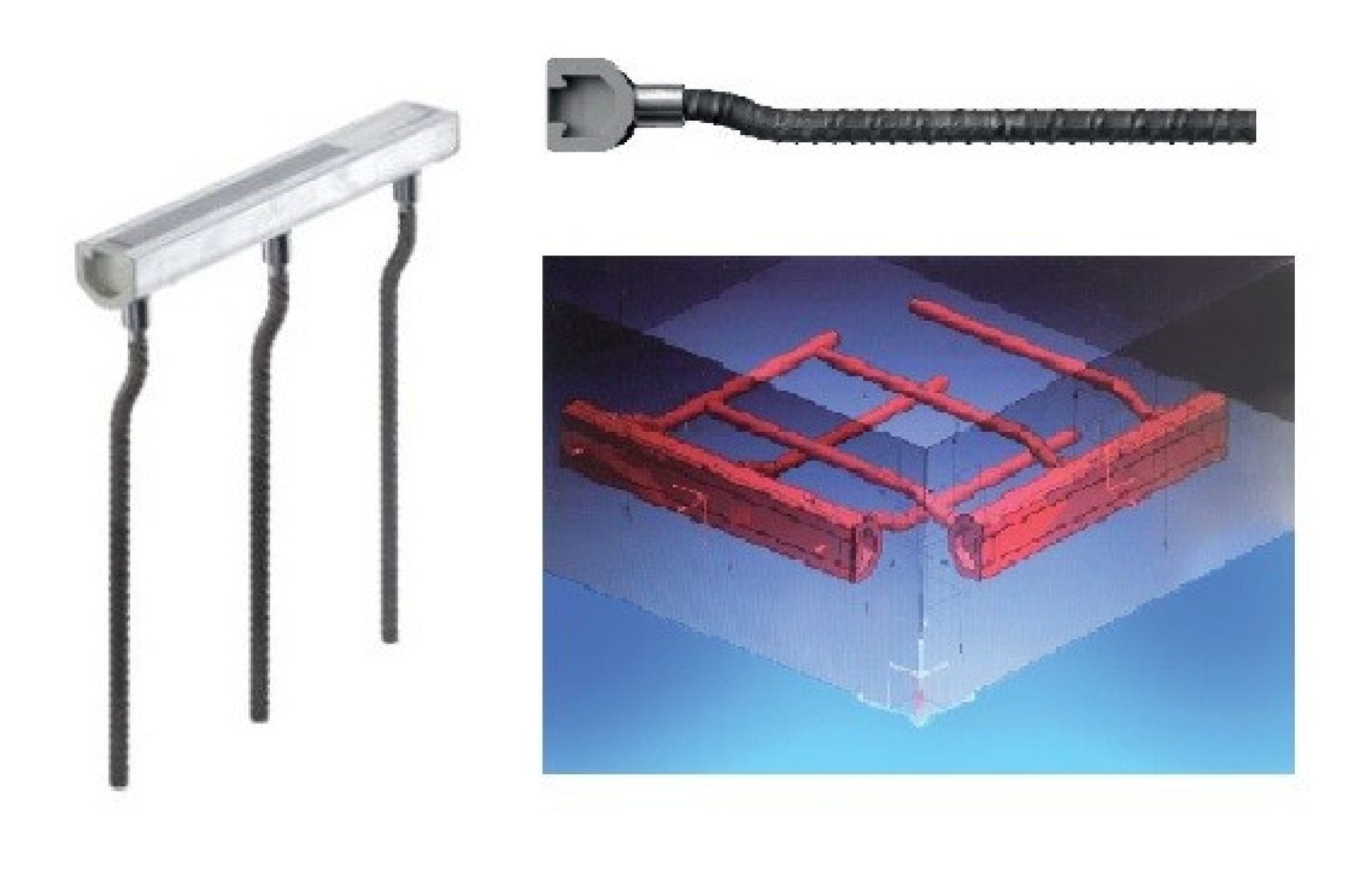

HAC Corner Solution

- New generation of cast-in anchor channels for face-of-slab corners

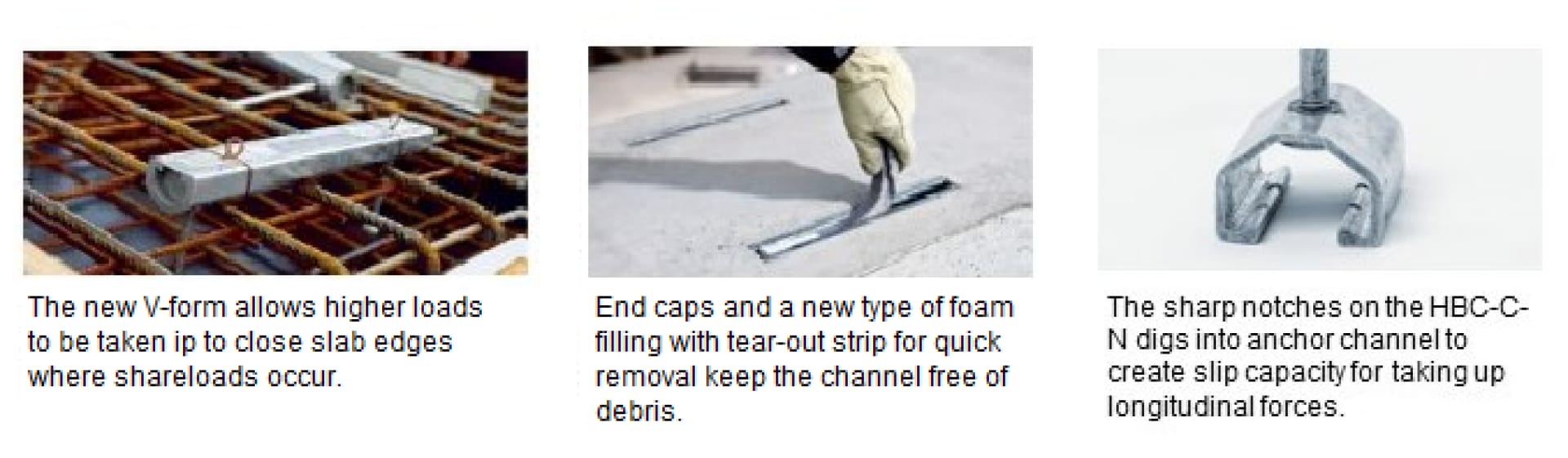

- The new corner piece features two separate anchor channels with special anchors based on reinforcement bars that overcomes the shortcomings of existing solutions:

- Easy installation through two separate channels

- Parallel shear loads supported by standard channels combines with notched bolts HBC-C-N

- The new assembly allows design based on existing codes such as CEN TS 1992-4 and codes for reinforced concrete including EC 2.

- Integration in PROFIS Anchor Channel for easy design

- Minimum corner distance

Download Documents