- Home

- Business Optimization

- Solutions

- Tool park Optimization

OPTIMISE YOUR TOOL PARK

Increase efficiency and reduce the cost of ownership

What tools do you have? Are they the most efficient or reliable tools for the job? Do you really need all of them? What are the direct and hidden costs of your tool ownership? Our dedicated productivity experts answer these questions and more, so you can optimise your tool park to fit the demands of your business and reduce overall costs.

Key jobsite productivity drivers

Using modern equipment

There are many brands and types of tools to choose from.

This seemingly straightforward choice of construction equipment and tools often affects the amount of time and effort required to complete a job, so can have a big impact on the productivity of a project.

Armed with the latest tools, your workforce can work more productively and if you choose a partner who can guarantee you support for when breakdowns occur, your business will avoid costly downtime due to unreliable tools.

Understanding the real costs of your tool park

Have you ever thought about how much your tools are really costing you?

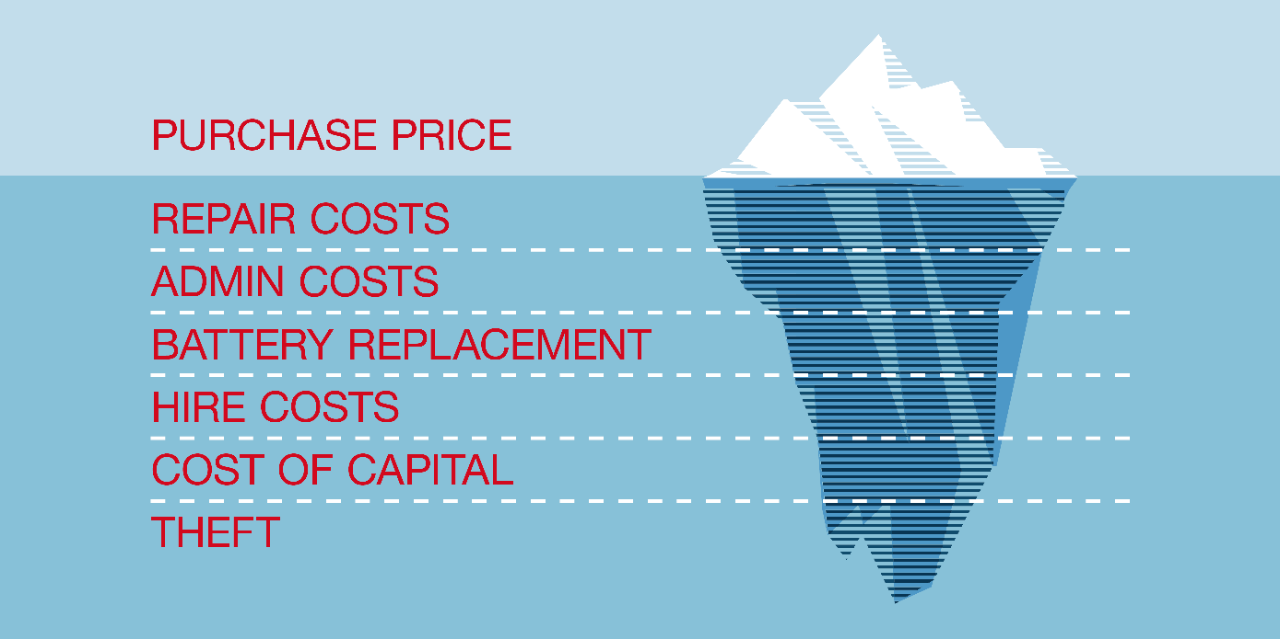

What you pay for the initial purchase of your tools is usually only the beginning as the cost of ownership comes with many direct and indirect fees. From repair and maintenance, calibration and batteries, to the time it takes to organise tools.

To calculate the true cost of your tools, you’ll first need to highlight the direct and indirect costs. The purchase price is often only the tip of the iceberg.

Managing safety and risk

The construction industry is particularly vulnerable to theft because there are often untested personnel onsite.

In order to reduce the risk of theft onsite, you need to have a clear record of all equipment and materials owned by your business. This encourages workers to take more care of their tools, leading to fewer lost or stolen items.

Having a clear record of everything also brings Health and Safety benefits as you can easily keep track of employee training certificates and calibration and service certificates to make sure your teams are operating safely with certified equipment.

Embracing digitization

When it comes to increasing productivity, adopting digital technology is the fastest path to the biggest payoff.

It’s important to have the ability to measure data on your construction sites and projects, such as how well your tools are being utilised, where your tools and equipment are and when your employee and calibration certificates are due.

This means you will be more informed on the areas in your business where you can make productivity improvements and save money.

How Hilti can help

Hilti’s tool park optimisation experts can help you understand the direct and hidden costs of your tool park, and help you make the changes that increase efficiency and lower costs.

We help you by:

- Assessing the number of tools you have onsite, in vehicles and in warehouses

- Uncovering hidden costs caused by repairs, administration and downtime

- Monitoring tool productivity and comparing with potential alternatives

- Working with you to discover the optimal type and number of tools required to meet your operating needs while meeting the highest safety standards

- Providing a demonstration so workers can try Hilti tools on-site in their everyday applications

- Advising you on the most effective way to manage your tool park

Ready to get started?